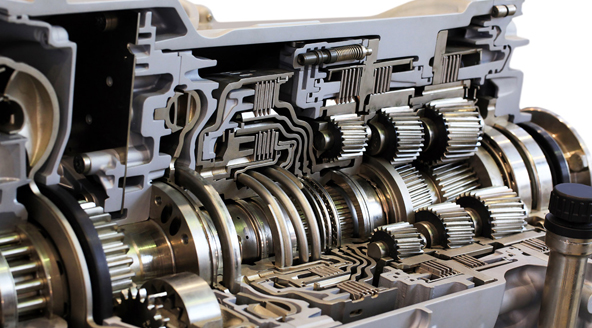

Refurbishment

Make is not an issue for refurbishment of gear boxes

All the gear internals will be cleaned by using high pressure washing machine for removing old oil contamination and sediments

Gears being checked for hardness and magnaflux NDT checking

Gear profiles can be measured by using PMM/Profile testers

Casing bores and centre distances will be measured by using CMM

After inspection, detailed inspection reports will be submitted to customer for joint inspection

After getting the P.O for components replaced, required spares will be manufactured by using state of the art most modern machineries

If other make gearboxes, gears being reversed engineering can be done by measuring profiles. Also, by using latest technology software, rating of the gearboxes can be improved

Sub assemblies being done by using induction heaters and liquid nitrogen whenever required

During trial running vibration, noise, temperature and oil leakages will be checked and AFIR will be prepared

Conducting seminar about basics of gears and maintenance of gearboxes